TEXAD: Sharing good practices

Several good practices were presented, as part of the first day at the TEXAD study visit to Sweden. The case studies covered several different aspects the management of textile waste – from skilling to working with public awareness.

After a brief presentation on Swedish legislation and regulations, seven different aspects/Good practices were presented.

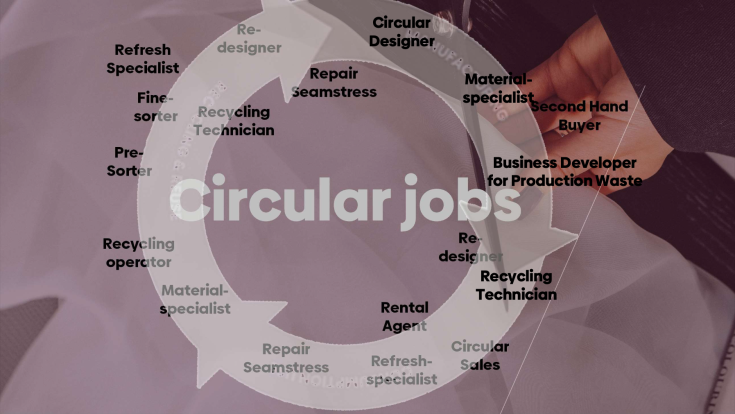

- The creation and skilling for Circular jobs. A presentation from the Nordic Textile Academy on how they work with skilling, re-skilling, and up-skilling. The school’s work depends on a near collaboration with the industry. And the ability to create a fast track for new skills, while still following the European Qualification Framework.

- The project System Demonstrator, by Science Park Borås. This project works with finding ways to work with Networking, Collaboration, Awareness, New projects, Testing, and Good practices within waste management. The Science Park Borås functions as a test bed for innovative projects and System Demonstrator is way of investigating how different solutions can be used systematically in textile waste management – in close collaboration with many different stakeholders.

- The logistics behind collection and sorting of textile waste. A presentation from the local municipal waste management company on how it investigates new ways to pre-sort the textile waste. For example, the company is an active partner of the earlier mentioned System Demonstrator and the Interreg project SorTex.

- Consumer Awareness projects, conducted by the Science Park Borås. A presentation on how the Science Park work with Consumer Awareness, based on their idea to have a holistic view on Textile waste handling. This includes the five dimensions: Technology, Business models, Policies/regulations, Behavioural actions, and the infrastructure of innovative systems. All based on their insights that you need to Scale up, Scale out, and Scale deep.

-

Valorisation at the Do-tank DO-tank Centre is the place where ideas become sustainable solutions through innovative processes – in collaboration between business, the public sector and scientific research. Here, ideas are exchanged, prototypes are developed and tests of future circular business models, products and services are conducted. A major focus is on prototyping and the valorisation of ideas, and the materials used.

- The Do Tank Garment Reparation line. An innovative project called Remake Factory. This project aims at teaching artificial intelligence (AI) to design new fashion garment using old clothes. The goal is to address the massive waste problem in the fashion industry, by transforming discarded textiles into stylish, sustainable clothing – connection AI, conveyors, robots, cameras, and more into a function resale system for damage clothes.

- Smart textiles. A showcase of materials and possible use of different textiles and fabrics. Part of Science Park Borås, showing the general audience what the future might bring. Smart textile is project driven, often when students work with different companies to find the new uses.

The study visit’s first day also included time for reflection, questions, and further discussion how all this affects policy making for the municipalities. And during the second days of the visit include a meeting with the Steering committee of TEXAD and a project management run-through.