Sustainable Materials Laboratory

About this good practice

Since 12/ 2021, Sustainable Materials Laboratory (SuMa), a new 300 m2 research and development facility has started its operation in the LAB University of Applied Sciences campus, Lahti, Finland.

SuMa was created as a part of an ERDF-funded project, which aimed to create a new research and development environment that could obtain more resources and expertise to provide new energy and circular economy services to companies, including piloting, testing, product development and demonstration facilities.

SuMa laboratory consists of 6 departments: analytical lab, pyrolysis, anaerobic digestion, plastic handling, textiles, and construction demolition waste.

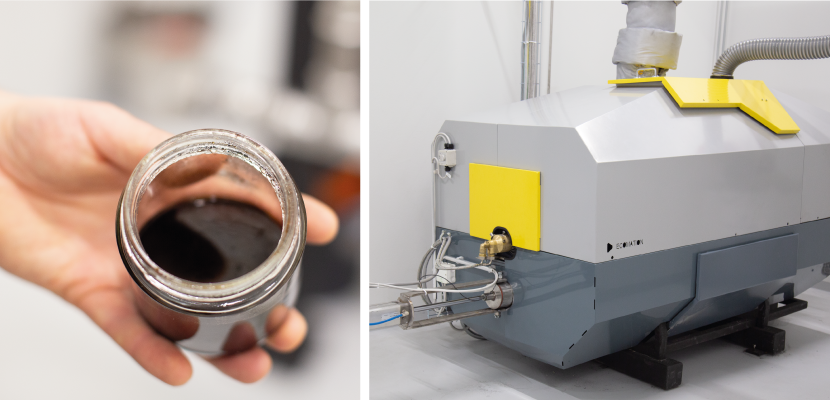

For instance, the pyrolysis reactor can be used to pyrolyze biomass, plastics, rubber and textiles. The equipment can be used for testing various materials to study the productivity of biochar and pyrolysis oil and their properties. Finding optimal process parameters with various materials can be offered as a service for companies that are planning to invest in pyrolysis. Biochar can be used as a soil improvement material that enhances the growth of trees and forests, which binds even more carbon dioxide from the atmosphere. Pyrolysis oil can replace light and heavy fuel oils. Bio-oil can be used in the manufacturing of high-added-value products, e.g. cosmetics and medical products.

The anaerobic digestion department is equipped with a reactor for studying and optimizing the digestion process with various biobased materials.

Expert opinion

Resources needed

SuMa was built and equipped by another project funded by ERDF and consisted of two overlapping stages (Stage 1: 1.9.2019-30.6.2022, Stage 2: 1.6.2020-31.10.2021).

Total budget of Stage 1: 625 043€ (410 680€ ERDF) - 517 710€ development activities, 107 333€ investments

Stage 2: 167 080€ investments

Evidence of success

SuMa offers commercial services for companies to develop new sustainable materials and products from recycled bio-based and technical materials. E.g., a new fastener product for wood-based construction materials was developed to replace a company's existing plastic fastener component with a new biocomposite material utilizing a side stream from the company's production.

Also, consults on biogas production and pyrolysis process utilizing the company’s side/waste streams are provided.

Potential for learning or transfer

SuMa works in synergy with already existing labs on the campus: wood technology laboratory, furniture laboratory, metalworking and machine laboratory, digital laboratory and laboratory of construction technology. SuMa deepens business cooperation and sustainable innovation in the region and increases the circular economy expertise at LAB by enriching research and education with state-of-the-art solutions, products, and technology.

The laboratories have the capabilities to research the effect of the usage of sustainable and recycled materials in various end products and applications. In addition, combining traditional manufacturing methods with new sustainable materials or developing completely new materials for traditional industries can be studied as well, without forgetting the digitalization of manufacturing processes, and material data control.

ERDF funding supporting RDI investments increases the exchange and cooperation between the university and surrounding companies.