IEA PRESS sludge press by Jochman - efficient for the resource recovery, and low energy consumption

About this good practice

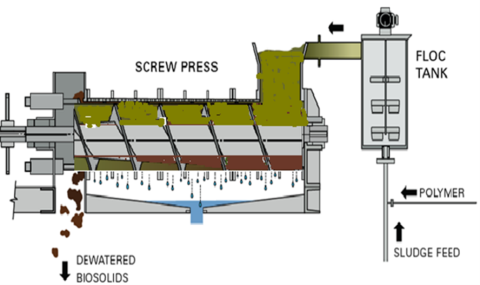

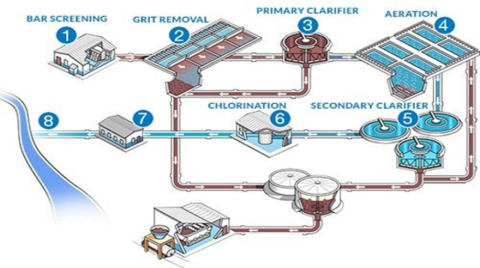

Wastewater treatment plants provide clean water by removing contaminants. The key by-product is sludge, a semi-solid residue rich in organic matter and pathogens. Sludge dewatering facilities are necessary to manage this waste after steps such as thickening, stabilization, dewatering, and disposal or reuse.

In sludge management, primary sludge is generated from the mechanical pre-treatment of the WWTP, and secondary sludge, which comes out of the biological treatment of the wastewater, are the most commonly encountered, and together they are treated to facilitate the final recovery of the sludge.

In order to process the sludge, it requires, in particular:

- stopping the spontaneous decomposition of organic matter

- hygienisation

- reducing the amount of the liquid component

Technologies such as sludge conditioning, thickening and dewatering aim to reduce the volume of sludge so that its subsequent treatment requires less energy, less technology, less space and is therefore less costly.

Essential for efficient and environmentally friendly wastewater treatment, screw sludge presses are versatile for both municipal and industrial applications and other demanding types. It is these screw sludge presses that are an important component of Jochman's industrial business.

Why an IEA Screw Press?

- Lowest energy demand

- Lowest wear (service costs about 1/10 compared to centrifuge)

- Very high operational lifetime

- Up to 30% cost saving for polymer

Resources needed

EU funded project with an NFP amount of EUR 351,270 aimed to introduce automation and electronic data systems in production. Additionally, the Support of Innovations project, with an NFP amount of EUR 697,620, aimed to innovate production processes and optimize production capacities.

Evidence of success

The IEA PRESS screw press is highly effective for sludge dewatering, with 40 machine types producing 10-2000 kg of dry matter per hour. In August 2023, tests at three wastewater treatment plants showed dry matter content of 21.5%-26.9%, demonstrating its efficiency. With over 1000 satisfied references, IEA screw filter presses have been delivered to 23 countries, including 17 in Europe, confirming their global success and high performance.

Potential for learning or transfer

Screw sludge presses are highly adaptable for both municipal and industrial wastewater treatment, handling diverse sludge types effectively. In municipal plants, they dewater waste activated sludge (WAS) and digested sludge from aerobic or anaerobic processes. In industrial settings, they serve food processing, chemical manufacturing, and pulp and paper industries, dewatering sludge from processes like dissolved air flotation (DAF).

Key Success Factors

• Versatility: Suitable for multiple sludge types and treatment scenarios.

• Efficiency: Enhances overall wastewater treatment efficiency.

• Cost-Effectiveness: Reduces storage and transportation costs by lowering sludge volume.

• Environmental Protection: Produces solid residue for safe disposal, mitigating environmental risks.

• Regulatory Compliance: Helps meet sludge disposal regulations.

Further information

Good practice owner

You can contact the good practice owner below for more detailed information.