Diffusing Industry 4.0 technologies in SMEs

Industry 4.0 implies the adoption in the industrial sector of technologies that have emerged and diffused in recent years (see Figure 1). It ranges from a variety of digital technologies such as 3D printing, the Internet of Things (IoT), and advanced robotics, to new materials such as bio- or nano-based, to new processes such as data-driven production, cybersecurity, artificial intelligence (AI) and synthetic biology (OECD, 2017).

Figure 1. Industry 4.0 involves Digital Technologies, New Materials and Processes. Source:

Small- and Medium-sized Enterprises (SMEs), which are defined by the European Commission as having fewer than 250 employees, an annual turnover of less than €50 million or a total balance sheet of less than €43 million, are the backbone of the European economy (Matt, Modrák, Zsifkovits, 2020). In 2015, SMEs employed 91 million people and generated €3934 billion of value added in the European Union. Industry 4.0 generates many new challenges for SMEs. Indeed, SMEs typically use enabling Industry 4.0 technologies less frequently than larger firms. In Europe, for instance, only 36% of surveyed companies with 50 to 249 employees use industrial robots, compared to 74% of companies with 1 000 or more employees (Fraunhofer, 2015). SMEs have limited funding capacities to invest in industry 4.0 technologies. Other challenges for SMEs to adopt industry 4.0 technologies are: changing business models, data issues, legal questions of liability and intellectual property, standards, and skill mismatches (Matt, Modrák, Zsifkovits, 2020).

Industry 4.0 offers SMEs the opportunity to boost their productivity and competitiveness through implementing highly efficient and automated manufacturing processes allowing for both mass-production and mass-customisation. As a result, regional policies must aim to reduce obstacles for SMEs to the uptake of industry 4.0 technologies with place-sensitive and SME-specific technological solutions.

The Interreg Europe project DIGITAL REGIONS aims to reinforce regional manufacturing sector with the uptake of industry 4.0 technologies in SMEs and increase the availability of Industry 4.0 skills in regional innovation ecosystems. Its main objective is to improve SMEs collaboration with other innovation actors to implement Industry 4.0 solutions: adopting a systemic approach, it aims to benefit quadruple helix stakeholders in regional innovation ecosystems, namely innovation policymakers, SMEs that use Industry 4.0 solutions, suppliers of Industry 4.0 services, universities, and innovation centres.

Some of the good practices identified within this project are worth a deeper look.

Digitalisation Parkour and the Open Platform

The Switzerland Innovation Park in Biel/Bienne (SIPBB), which is part of the Switzerland Innovation Foundation has an interesting experience of diffusing Industry 4.0 technologies in SMEs. The Switzerland Innovation Foundation is the umbrella organisation that coordinates five innovation sites in Switzerland, markets them abroad, and manages the federal loan guarantees (about CHF 70 million guarantees per innovation site). The objectives of Switzerland Innovation are to:

- Generate research investment from abroad

- Promote Swiss innovation performance

- Accelerate the implementation of research results into marketable products

- Support start-ups

- Promote test and demonstration platform

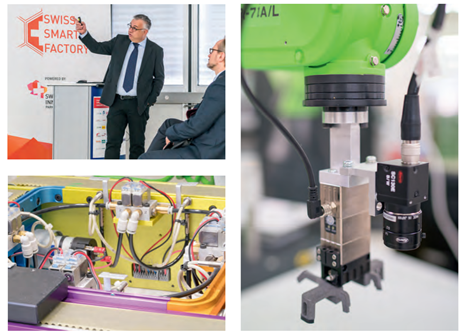

The Switzerland Innovation Park in Biel/Bienne (SIPBB) operates industrial demonstration systems such as Digitalisation Parkour that illustrate the practical potential of Industry 4.0 for SMEs. Digitalisation Parkour, is a demo-space of industry 4.0 technologies to SMEs designed by the Swiss Smart Factory. It consists of interactive demo stations on industry 4.0 technologies where SMEs can directly experience the impact of each technology on their industrial activities: Industrial Internet of Things (IIoT), Robotics, Blockchain, Cryptocurrencies & Smart Contracts, Cloud and Edge Computing, Augmented Reality and Virtual Reality, Artificial Intelligence and Smart Data, and Workplace of the Future. The demo-space is an application-oriented centre of competence dedicated to transferring Industry 4.0 technologies to SMEs. It also offers the opportunities to collaborate through an open living lab and is accessible to a broad public.

Photos: Swiss Smart Factory (SSF).

The Switzerland Innovation Park in Biel/Bienne (SIPBB) created the Open Platform for the Adoption of Digital Innovation to support the exchange of knowledge and best-practices for the adoption of digital technologies for SMEs. The open platform is coordinated by a third-party (non-profit organisation) that provides supports such as services for demonstration, prototyping, testing, networking opportunities, sharing best practices, sharing methodologies for helping SMEs to adopt digital technologies. The initiative complements Digitalisation Parkour to enhance collaboration, networking opportunities and the program’s accessibility for a wide range of SMEs.

|

Interview with Dr.-Ing. Dominic Gorecky, Head of Swiss Smart Factory, Biel/Bienne, Switzerland Arnault Morisson: What recommendations would you give to policymakers pursuing similar Industry 4.0 good practices?Dominic Gorecky: When creating a new initiative, sustainability is a key. Therefore, you must assess and analyse your regional economic structures and needs. Make sure that your initiative is addressing an actual need and is not redundant to existing initiatives. The digital transformation affects every domain and sector, but you might set your focus for example on the digital technologies in textile and footwear industry, if your region is a stronghold in this area. Second, make digital innovation tangible! To do so, you will need a state-of-the-art test and demonstration environment. This infrastructure can be time-consuming and costly to set-up and to operate. Involve regional stakeholders, share your vision with them and bring them on-board to build-up and co-finance your infrastructure. |

The Co-Learning Lab

A similar approach has been taken in North Bavaria (Germany), where Hof University and Kronach Innovation Centre have launched the Co-Learning Lab, an initiative to promote the adoption of Industry 4.0 technologies for SMEs. The initiative provides an example of university-industry collaboration to offer employees in the industrial sector the opportunity to learn about digital industrial technologies and thus for the industrial sector to gain in competitiveness. The Co-Learning Lab first performs a diagnostic to assess the SMEs’ level of digital transformation; workshops are then devised to respond to digital bottlenecks in regional industrial companies. Workshops are using agile prototype design thinking and experiment with new digital tools and methodologies such as data visualisation, virtual reality, 3D printing, and robotics. Workshops have proven to be a good medium to address digital bottlenecks in industrial companies. Moreover, the Co-Learning Lab shows the importance to combine agile design thinking methodologies with access to advanced digital industrial technologies. Soft and hard skills must be addressed at the same time to upskill employees.

From these good practices, three insights can help regional policymakers when designing policies to support the uptake of Industry 4.0 technologies in SMEs.

- Regional policies to support the uptake of Industry 4.0 in SMEs are more relevant for regions in which the high-technology industrial sector represents an important share of the regional economy (>20%) and in which private industrial companies are open to collaborate with one another.

- Regional political commitments and industrial supports are key to implement such initiatives. Moreover, university-industry collaboration to design and implement programs to feature demo-spaces and to upskill workers contributes to positive outcomes.

- Regional policymakers must not only focus on the strategic design of such initiatives but also dedicate efforts for the implementation, as demo-stations will require frequent updates and technical staff upskilling. Monitoring such initiatives is important for frequent upgrades. A set of key performance indicators (KPIs) must be in place to monitor outreach and follow-up projects.

Further resources

- Learn more about Interreg Europe project DIGITAL REGIONS

- Learn more about the good practice Digitalisation parkour

- Learn more about the good practice Open Platform for the Adoption of Digital Innovation

- Learn more about the good practice the co-learning lab